In the world of design and printing, gold stamping, silver stamping, and laser foil stamping are considered three of the most powerful decorative techniques. These methods not only enhance the visual appeal of products but also significantly elevate their overall quality. In this article, we will explore the foundational knowledge, unique characteristics, applications, and how to make an informed choice based on your needs.

Gold Stamping

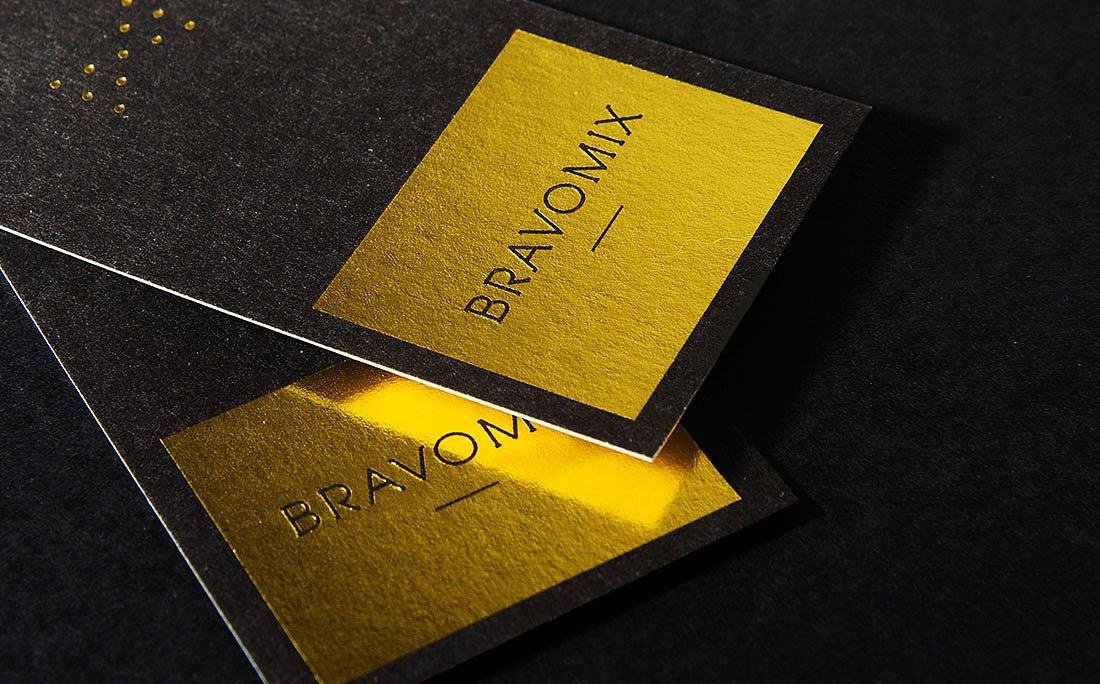

Gold stamping involves applying metallic foil onto a printed surface using heat, resulting in a gold-colored logo or design. This process can be divided into two types: hot stamping and cold stamping. Hot stamping relies on pressure and temperature to transfer the foil from the metallic plate to the substrate, while cold stamping uses UV printing adhesives to directly transfer the foil without additional heating.

- Features and Applications:

- Decorative Appeal: Gold stamping significantly enhances the product’s visual appeal and luxury, often used on logos, brand names, and other key information on packaging, thereby adding value to the product.

- Anti-counterfeit: Gold stamping can provide excellent anti-counterfeit protection by using holographic stamping technology, effectively preventing counterfeit products.

- Material Adaptability: This technique is adaptable to various materials, such as paper, plastic, wood, and leather, offering flexibility in product decoration.

- Font Size Restriction: To avoid smudging or blurry edges, the text size must be no smaller than 7pt.

- Cost and Technical Requirements: Gold stamping can be more costly in terms of materials and technical expertise, and the production cycle is relatively long, which may limit its widespread use.

In summary, gold stamping is an effective decorative process for elevating product aesthetics and anti-counterfeit features, with flexibility in material application. However, it may face restrictions related to font size, cost, and production time.

Silver Stamping

Silver stamping operates similarly to gold stamping, but with silver foil. It applies a silver-colored finish to printed materials, giving products a unique visual effect. The process involves the same heating and foil transfer methods as gold stamping.

- Features and Applications:

- Visual Appeal: Silver stamping offers a luxurious silver effect, which stands out for its uniqueness compared to gold, providing a modern, sophisticated touch.

- Application Scenarios: This technique is widely used in various packaging applications, especially where a silver aesthetic is desired.

- Material Compatibility: It works well with materials such as paper, plastic, wood, and leather, much like gold stamping.

- Considerations and Limitations:

- Font Size Requirement: To avoid fuzzy edges, text should be at least 7pt.

- Cost and Production Time: Like gold stamping, silver stamping also involves higher costs and longer production times, limiting its broader application.

Laser Foil Stamping

Laser foil stamping utilizes laser ink and advanced printing techniques to create unique optical effects, such as multi-color or changing visual effects depending on the angle of observation. This process is more complex and harder to replicate, adding exceptional value and appeal to printed materials.

- Features and Applications:

- Advanced Anti-counterfeit: Laser foil stamping provides outstanding anti-counterfeit protection, making it highly effective for labels and products where security is a priority.

- Visual Spectacle: Under light, laser foil stamped labels produce dazzling effects like shimmering glows and a 3D feel, offering a truly captivating visual experience.

- Wide Application: This technology is used for packaging high-end consumer products, pharmaceuticals, electronics, and more, boosting both brand image and market competitiveness.

However, laser foil stamping has a few drawbacks:

- Cost Considerations: The materials and technical expertise required for laser foil stamping tend to increase production costs.

- Protection Requirements: Due to the unique laser effects, special care is needed to protect the surface of products, preventing scratches and wear during storage and transportation to maintain the aesthetic and integrity.

MPAKES Printing: Bringing Foil Stamping to Life

Integrating MPAKES Printing with gold stamping, silver stamping, and laser foil stamping can significantly enhance your product’s quality and market appeal. With 15 years of experience and state-of-the-art equipment, MPAKES can deliver high-quality hot stamping, silver stamping, and laser foil stamping services, offering a wide range of decorative options to elevate your products.

MPAKES Printing and Gold Stamping

MPAKES provides precise gold stamping services, perfect for product packaging, book covers, and promotional materials. Using Heidelberg printing presses and advanced hot stamping technology, MPAKES ensures high-precision gold effects, boosting your product’s luxury feel and brand value. This technique not only enhances visual impact but also provides excellent anti-counterfeit features.

MPAKES Printing and Silver Stamping

MPAKES offers silver stamping that brings a modern and sophisticated design flair to your products. Ideal for electronics, jewelry packaging, and food packaging, silver stamping gives your brand a distinctive edge. Whether on paper, plastic, or leather, MPAKES ensures flawless silver effects, giving your packaging a refined, high-end appearance.

MPAKES Printing and Laser Foil Stamping

MPAKES integrates laser foil stamping technology, delivering dynamic and multi-dimensional visual effects that significantly enhance the product’s uniqueness. With UV printing equipment and specialized laser foil stamping tools, MPAKES ensures your product has an exclusive look that is hard to replicate. It is the perfect choice for high-end goods, pharmaceuticals, and limited edition items requiring high-level security and visual appeal.

Why Choose MPAKES Printing?

- Rich Experience: With over 15 years of experience, MPAKES offers end-to-end solutions from design to printing, ensuring timely delivery and top-notch quality.

- Advanced Equipment: MPAKES uses Heidelberg printing presses and other imported equipment to ensure precision and high-quality results for all foil stamping techniques.

- High-Quality Assurance: Whether it’s gold, silver, or laser foil stamping, MPAKES guarantees meticulous attention to detail, ensuring accurate color reproduction and flawless finishing.

- Custom Solutions: MPAKES offers tailored printing solutions that meet the specific needs of each product, ensuring the perfect combination of design and functionality.

Conclusion

By integrating MPAKES Printing with gold, silver, and laser foil stamping, your products can achieve an unparalleled visual impact and brand differentiation. Whether your goal is to enhance brand image, improve anti-counterfeit capabilities, or simply elevate the luxury appeal of your packaging, MPAKES is your trusted partner.

For custom solutions and expert advice, feel free to reach out to MPAKES, and we’ll help bring your vision to life with precision and excellence.